The LAP Pallet

THE PROBLEM

Companies face key challenges when it comes to transport pallets:

- Increasing regulatory pressure: Documentation and other obligations relating to CO₂, origin, and recycling are increasing (CSRD, EUDR, PPWR).

- Cost pressure: Wood, plastics, and even recycled materials are becoming more expensive—particularly due to global shortages and volatile markets.

- No data transparency: The material composition and use of pallets is usually opaque—there is a lack of documentation.

OUR SOLUTION

Logistic Arts Production (LAP) GmbH provides an alternative load carrier.

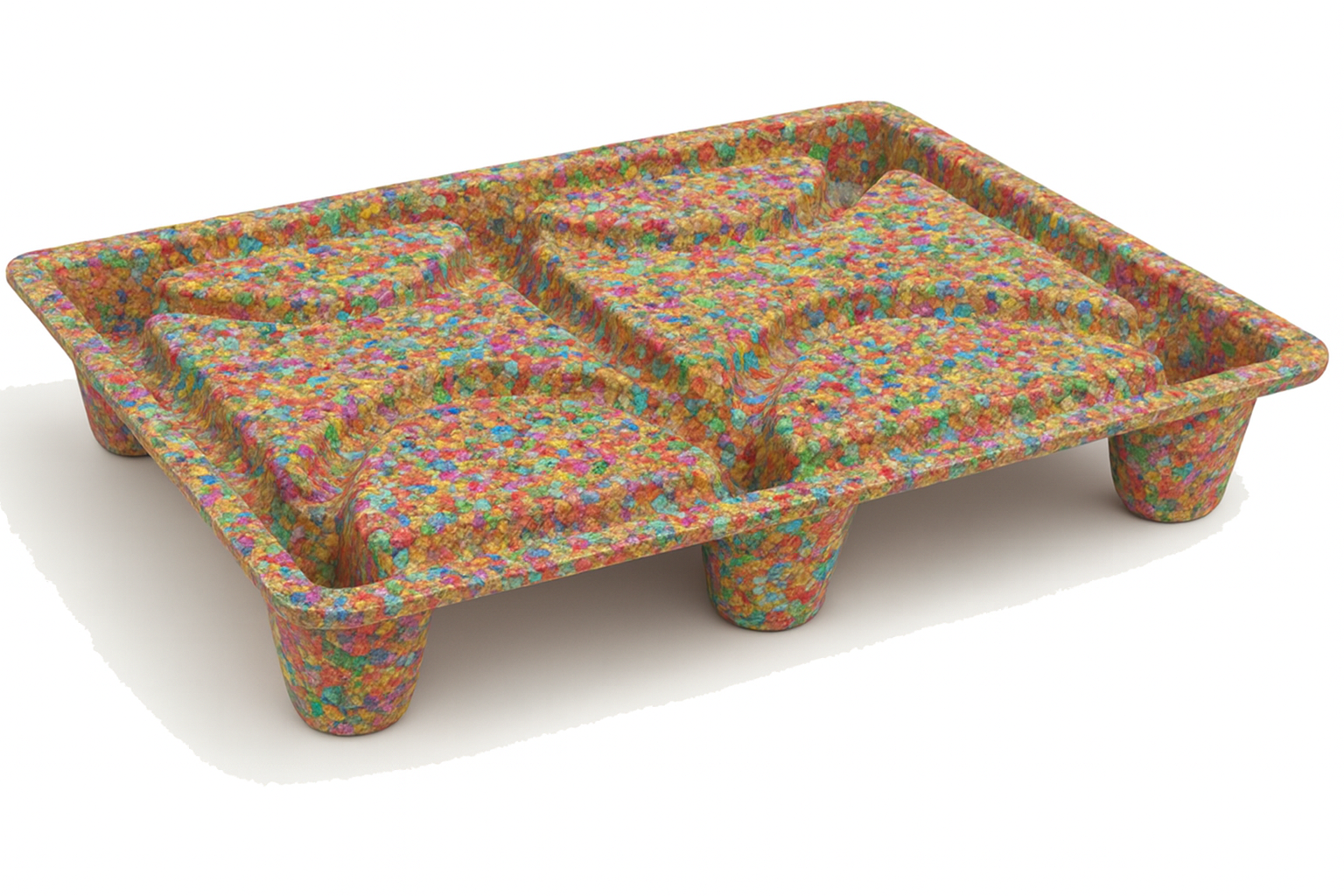

The product is based on a new manufacturing process in which waste wood and used plastics can be compressed using hot air to form a stable, high-quality pallet. The process enables low manufacturing costs as it does not use expensively processed plastic recyclates, but rather problem material flows.

PROPERTIES

- No harmful substances or contaminants thanks to evaporation during the pressing process at up to 200°C

- Defective pallets can be reground multiple times and returned to production

- Improved ESG score through the use of problematic material flows and traceability

- Industrially standardized, high load capacity. Easy integration into existing processes.

- Transparency regarding material properties possible for compliance with documentation requirements